Revolutionizing Industry with Smart Replicas

A digital replica of a physical asset or process that evolves over its lifecycle, covering products, machines, production systems, and supply chains.

Key Advantages:

- Merges real-time data with digital simulations to optimize operations.

- Cuts costs by reducing reliance on physical prototypes.

- Empowers data-driven decisions through predictive insights.

Key Functions:

- Combines real and digital worlds to optimize design and production.

- Reduces the need for physical prototypes and lowers costs

- Models industrial assets with geometry, kinematics, and behavior for simulation, control, and improvement.

Itndustry Applications:

Manufacturing

Enhance production and product quality.

Energy

Boost asset performance and minimize downtime.

Supply Chain

Improve visibility and streamline logistics.

Our Expertise:

- Custom solutions for seamless integration and growth.

- Dedicated support to ensure maximum value

SUN-THUR : 9am – 5pm

+966 566 994507

Features of Digital Twin

Document Management

Centralized storage of all documents (e.g., drawings, instructions) associated with equipment.

Simulation

Models equipment behavior in virtual environments Facilitates testing and scenario analysis without physical risks.

Model Synchronization

Aligns digital models with real-world parameters. Supports real-time updates for improved accuracy.

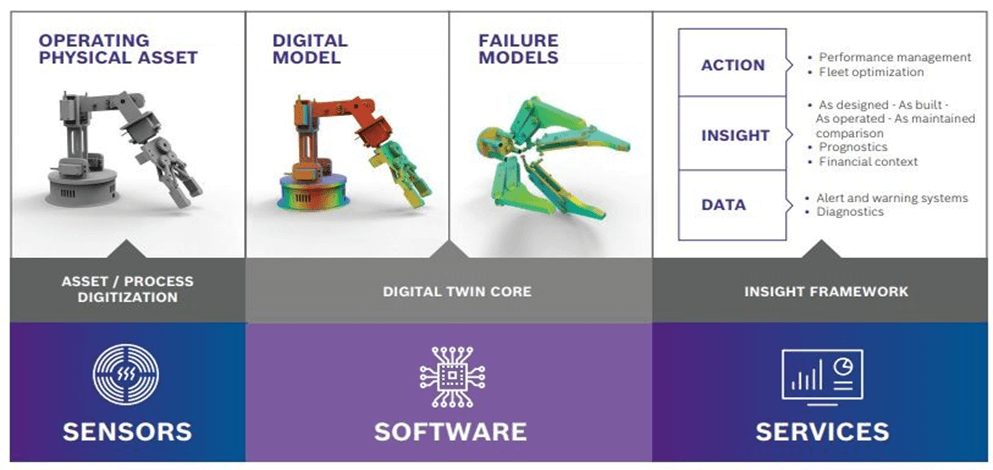

Digital Model

Creation of digital representations of equipment. Simulates properties and behaviors of physical devices for analysis.

Data Model

Provides standardized frameworks for connectivity, analytics, and visualization.

Connected Analytics

Leverages algorithms to analyze measured properties of physical devices. Provides actionable insights through computational results.

3D Representation

Maps measured or simulated properties of physical devices into 3D digital models.

Visualization

Offers graphical representations on supervisory screens or personal devices. Enables intuitive interaction and monitoring.

Digital Twin – Key Benefits

By leveraging AI, the digital twin not only mirrors real-world processes but also predicts outcomes, optimizes performance, and supports decision-making across all operational levels

Enhanced Product Design

Simulate and test new designs virtually to reduce prototyping costs and improve innovation

Predictive Maintenance

Identify faults and prevent breakdowns, minimizing downtime and reducing operational costs

Optimized Supply Chains

Model logistics to foresee

delays, streamline operations, and improve resource allocation

Improved Operational Efficiency

Real-time monitoring and simulation improve decision-making, reduce costs, and enhance equipment lifespan

Enhanced Safety

Simulate risks and improve safety measures, reducing hazards and operational vulnerabilities

Improved Customer Engagement

Provide interactive, customized experiences to improve satisfaction and increase conversions

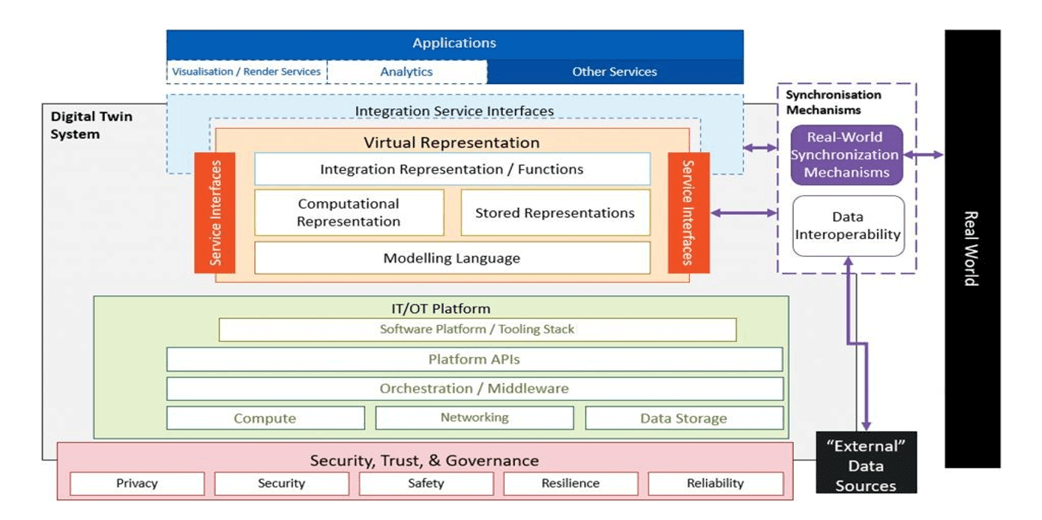

Digital Twin Platform Stack Architectural Framework

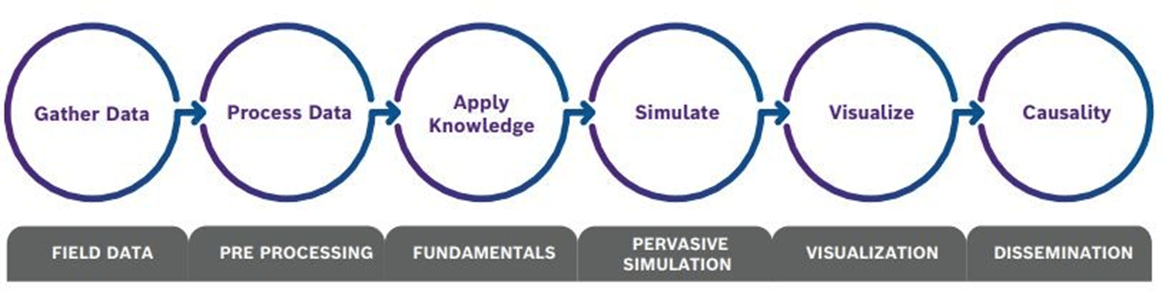

Building the Digital Twin

The modern Digital Twins are dynamic software models of assets or processes that enable real-time monitoring and improve process efficiencies.

Building the Digital Twin - Prerequisites

Access to apt historical data and acquiring relevant real-time data

This is a prerequisite for any solution that requires predicting outcomes based on current and past data. Rich historic fault data of industrial assets, high-quality operational and process data of the ecosystem form the basis of building a robust prediction mechanism.

Data integration

This is required to represent a real-world object by different subgraphs of nodes and edges. The integration of the different nodes results in creating a laminar data flow thus helping us to construct the visual abstract, which represents the anatomy of a Digital Twin.

Fidelity and Allegiance

This is essential to mirror assets or processes from its physical form by creating High Fidelity Simulation (HFS) models thus enabling operations to run on virtual machines. This evolves as footing for increasing the awareness on the asset or the process incorporating diverse operating scenarios.

IoT Communication Grid

This is vital to establish ubiquitous data connectivity to enable computational intelligence powered by both wired and wireless technologies.

Digital Twins: Transforming Industries, One Use Case at a Time

Manufacturing

- Design customization.

- Simulation and validation of each development step.

- Enhancing operational processes.

- Reducing the overall cost of engineering.

- Predictive maintenance.

- Virtual monitoring and performance management.

Construction/Real Estate

- Automated project control.

- Safety monitoring.

- Project planning and logistics.

- Building performance assessment.

- Smart space capacity evaluation and design.

- Quality assessment.

Utilities

- Power grid planning.

- Enhanced visibility of the physical grid.

- Efficiency improvement of the grid.

- Power grid self-evaluation.

- Ecological reconstruction of the grid.

Aerospace/Automotive

- Design customization.

- Defect detection.

- Aircraft tracking.

- Weather condition stipulation.

- Transport load optimization.

- Vehicle defect detection.

- Real-time monitoring and predictive analytics.

Agriculture/Farming

- Advanced smart farming.

- Planning, monitoring, and controlling farm processes.

- Weather prediction.

- Stress identification.

- Livestock monitoring and management.

Healthcare

- Diagnosis and therapy.

- Preventive treatments.

- Drug development.

- Medical device utilization.

- Facility and operations design.

- Education and training.

Mining

- Track & optimize the performance of equipment

- Plan excavation sequences

- Monitor air quality, vibration, and noise levels

- Optimize energy consumption

- Monitor underground and surface operations

- Provide realistic simulation-based training

Retail

- Supply chain optimization.

- Product inception, development, and distribution.

- Fleet management and route efficiency.

- Facility and operations design.

AI powered Digital twin

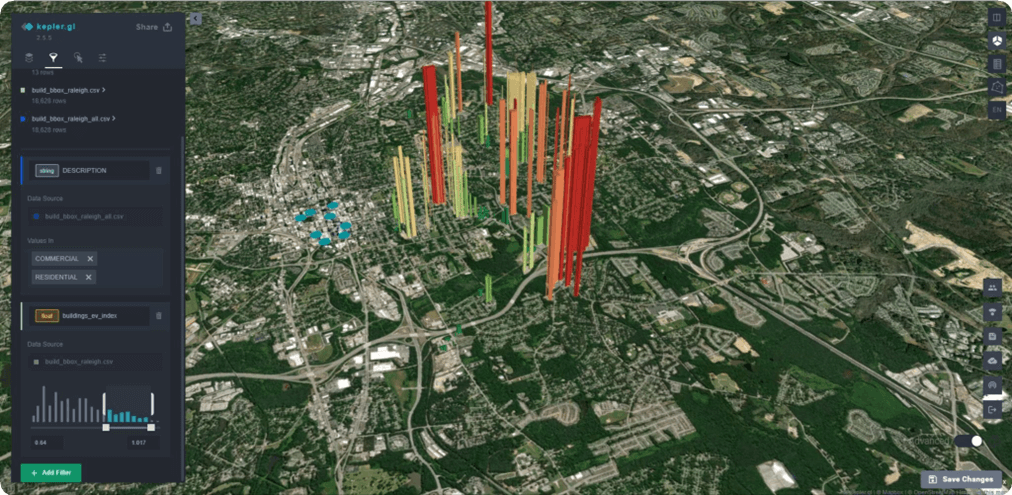

Where should we put EV charging stations in a city

AI powered Digital twin

Real life demo of a chemical plant with IoT Sensor

AI powered Digital twin

How to navigate inside of an airport

AI powered Digital twin

Dubai Real Estate Data Enabled Digital Twin

Clients